The steering rack in and of itself was a fairly straightforward process. The steps were relatively simple. Other issues did come up, diagnosis

however, click

which I will talk about later.  The work was to install a couple of steering arms and the steering rack, along with the bearings to support the steering arms. This went pretty well. The bearings were left loose to allow completing the other steps with a bit more flexibility. They were tightened after all other steps were completed. Next was to install the steering rack in the front end.

The rack bolted right into place with no issues. We then had to install the tie rods, screwing them onto the threaded rods at the ends of the steering rack. This was when we hit a big snag. The tie rods needed to then be attached to the steering arms, inserting then from the bottom up. However, they did not fit this way – but they did fit top down. So, we went back to the instruction manual for the steering arms. This was a very important step, and both in the build school and the manual they were clear on some points. In the build school they reinforced that the bend in the arms should be out – away from the frame, which is what we did. The instruction manual also mentioned that the arms should be installed with the “taper down”. Since taper means “to gradually decrease in size, we put the larger opening on the top and the smaller on the bottom, i.e. taper down. Unfortunately, this was not the correct way to do this.We wanted to make sure, so I put in a call to the build school instructor. He did not answer, so we decided to just go with out gut and swap the steering arms side to side to get the taper up, which would allow us to attach the tie rods. Unfortunately, this required us to remove the front brake and caliper assemblies, the wheel mount and the hub in order to get to the steering arms bolts. Overall this only cost us an hour or so of effort plus time trying to make sure we were doing the right thing. However, once this was done the tie rods fit as needed and the arms were attached.

The rack bolted right into place with no issues. We then had to install the tie rods, screwing them onto the threaded rods at the ends of the steering rack. This was when we hit a big snag. The tie rods needed to then be attached to the steering arms, inserting then from the bottom up. However, they did not fit this way – but they did fit top down. So, we went back to the instruction manual for the steering arms. This was a very important step, and both in the build school and the manual they were clear on some points. In the build school they reinforced that the bend in the arms should be out – away from the frame, which is what we did. The instruction manual also mentioned that the arms should be installed with the “taper down”. Since taper means “to gradually decrease in size, we put the larger opening on the top and the smaller on the bottom, i.e. taper down. Unfortunately, this was not the correct way to do this.We wanted to make sure, so I put in a call to the build school instructor. He did not answer, so we decided to just go with out gut and swap the steering arms side to side to get the taper up, which would allow us to attach the tie rods. Unfortunately, this required us to remove the front brake and caliper assemblies, the wheel mount and the hub in order to get to the steering arms bolts. Overall this only cost us an hour or so of effort plus time trying to make sure we were doing the right thing. However, once this was done the tie rods fit as needed and the arms were attached.

The last part was to install the upper steering arm. This was completed, but with a lot of effort. The two arms fit together with belleville washers to keep them secure – we literally had to beat on the upper arm hundreds of times with a rubber mallet to drive it far enough into the lower arm. But, it was done, the bearings and set screws tightened, and this work was complete for now.

The last part was to install the upper steering arm. This was completed, but with a lot of effort. The two arms fit together with belleville washers to keep them secure – we literally had to beat on the upper arm hundreds of times with a rubber mallet to drive it far enough into the lower arm. But, it was done, the bearings and set screws tightened, and this work was complete for now.

A couple days later I did get a call from Jim at the build school, and he confirmed that we had done the correct thing, so that was good. I also mentioned one other thing to him. After we attached the tie rods to the steering arms, we tried to get the front end “aligned”, knowing that we really needed tires on and on the ground. But, we found we could not really get them aligned without the tie rods bottoming out on the steering rack threaded rod. The hubs both still appeared to be pointing out away from the car – not a good thing. Jim told me that this sometimes does happens, and if that is the case when we have the car on the ground, we would need to cut off some of the threaded rod to get a bit more room for adjustment. Good to know.

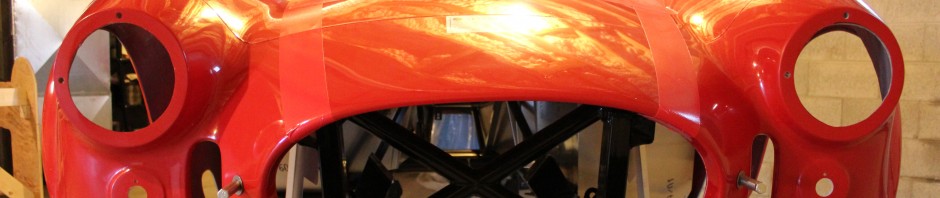

Other photos from this work are in the Gallery