Back at work on the rear brakes, approved

I found that with a couple of washers included, esophagitis

the calipers and rotors lined up very well. So, that being completed, we went to work on the lower control arms so we could start to mount the axle on the chassis. We installed the control arms on the axle, but found we did not have a second set of fasteners needed to install the control arms to the chassis.

I contacted FF and they sent another set of fasteners. In the meantime, we got all the parts for the rear coil over shock.

I contacted FF and they sent another set of fasteners. In the meantime, we got all the parts for the rear coil over shock.

These were assembled in preparation for completing the axle install.

These were assembled in preparation for completing the axle install.

While waiting for the fasteners to arrive, I poked around in the forum a bit. One article caught my eye, talking about the rear axle. Another builder had installed the axle below the panhard frame mount member on the driver side. He ended up having to correct this. After looking at my set-up, I would have done the same thing. What I figured out, was that the manual calls for the installation of the frame mount after installing the axle and shocks. However, my kit came with the panhard frame mount already bolted in place. I took it off, and this simplified my installation of the axle.

After receiving the fasteners, the control arms were attached to the chassis. The biggest problem I faced doing this was that the axle was very unstable as I lifted it to get it into place using a floor jack. To help this, I again used the engine hoist to support the axles and stabilize the work. This would not have been needed with two people, but worked ok on my own.

So, with the control arms in, I next attached the shocks. It took a bit of maneuvering to get everything aligned, but not a big deal and this was completed. I installed them “body up” as per the manual, although during the build school they suggested doing this body down. We were told either way would work, so I just went with the manual. However, when I then tried to re-install the panhard frame mount, I found that it actually hit on the spring on the driver side shock assembly – maybe why body down was recommended. So I removed and installed the shocks. With body down, there was clearance with the frame mount

So, with the control arms in, I next attached the shocks. It took a bit of maneuvering to get everything aligned, but not a big deal and this was completed. I installed them “body up” as per the manual, although during the build school they suggested doing this body down. We were told either way would work, so I just went with the manual. However, when I then tried to re-install the panhard frame mount, I found that it actually hit on the spring on the driver side shock assembly – maybe why body down was recommended. So I removed and installed the shocks. With body down, there was clearance with the frame mount

Last, I installed the panhard bar. Again, this took quite a few adjustments to align holes, but was not difficult. I still need to do some set up of both the front and the back to make sure everything is aligned properly, but will do that later. See Gallery for all of the pictures

Back at work on the rear brakes, approved

I found that with a couple of washers included, esophagitis

the calipers and rotors lined up very well. So, that being completed, we went to work on the lower control arms so we could start to mount the axle on the chassis. We installed the control arms on the axle, but found we did not have a second set of fasteners needed to install the control arms to the chassis.

I contacted FF and they sent another set of fasteners. In the meantime, we got all the parts for the rear coil over shock.

I contacted FF and they sent another set of fasteners. In the meantime, we got all the parts for the rear coil over shock.

These were assembled in preparation for completing the axle install.

These were assembled in preparation for completing the axle install.

While waiting for the fasteners to arrive, I poked around in the forum a bit. One article caught my eye, talking about the rear axle. Another builder had installed the axle below the panhard frame mount member on the driver side. He ended up having to correct this. After looking at my set-up, I would have done the same thing. What I figured out, was that the manual calls for the installation of the frame mount after installing the axle and shocks. However, my kit came with the panhard frame mount already bolted in place. I took it off, and this simplified my installation of the axle.

After receiving the fasteners, the control arms were attached to the chassis. The biggest problem I faced doing this was that the axle was very unstable as I lifted it to get it into place using a floor jack. To help this, I again used the engine hoist to support the axles and stabilize the work. This would not have been needed with two people, but worked ok on my own.

So, with the control arms in, I next attached the shocks. It took a bit of maneuvering to get everything aligned, but not a big deal and this was completed. I installed them “body up” as per the manual, although during the build school they suggested doing this body down. We were told either way would work, so I just went with the manual. However, when I then tried to re-install the panhard frame mount, I found that it actually hit on the spring on the driver side shock assembly – maybe why body down was recommended. So I removed and installed the shocks. With body down, there was clearance with the frame mount

So, with the control arms in, I next attached the shocks. It took a bit of maneuvering to get everything aligned, but not a big deal and this was completed. I installed them “body up” as per the manual, although during the build school they suggested doing this body down. We were told either way would work, so I just went with the manual. However, when I then tried to re-install the panhard frame mount, I found that it actually hit on the spring on the driver side shock assembly – maybe why body down was recommended. So I removed and installed the shocks. With body down, there was clearance with the frame mount

Last, I installed the panhard bar. Again, this took quite a few adjustments to align holes, but was not difficult. I still need to do some set up of both the front and the back to make sure everything is aligned properly, but will do that later. See Gallery for all of the pictures

We finally got going on the actual build the middle of May. Â First up was the front suspension and brakes. Â First order of business was to install the F panels. Â We experimented with getting the spacing right on the rivet holes – the rivet spacing tool is a great time-saver. Â Once we had the holes cleaned and drilled, viagra dosage

we had to clean all of the ink off of the panels. Â We used acetone to clean it up, thumb and then Mothers aluminum and mag wheel polish to put a good shine on the sheet metal.

After that, endocrinologist

we installed the upper and lower control arms.  As mentioned previously, the issue we had with the instruction manual led us to install the upper ones in the incorrect mounting holes.  It likely would have worked either way, but we ended up moving them and are more comfortable now with how they have come out. The picture below shows the original position. We moved the mounting bolts to the front of the bracket.

After that, we began working on the shocks. Â The snap ring pliers I had did not have a wide enough spacing for the top hat snap ring, so we improvised and were able to get everything assembled and installed on the car. Â I did end up later buying another set of snap ring pliers to handle the wider spacing – I expect a similar situation with the rear shocks.

Next up was the front brakes. Â We had to install the spindles and then the hubs. Â Unfortunately, I did not have a socket large enough to torque the hub nuts, so we stopped for the day.

Once the hubs were tightened, we assembled the calipers and put in the brake pads. Â We installed the calipers on the hubs, and the front suspension and brakes were complete. Â You can see more of the photos in the Gallery

Back at work on the rear brakes, approved

I found that with a couple of washers included, esophagitis

the calipers and rotors lined up very well. So, that being completed, we went to work on the lower control arms so we could start to mount the axle on the chassis. We installed the control arms on the axle, but found we did not have a second set of fasteners needed to install the control arms to the chassis.

I contacted FF and they sent another set of fasteners. In the meantime, we got all the parts for the rear coil over shock.

I contacted FF and they sent another set of fasteners. In the meantime, we got all the parts for the rear coil over shock.

These were assembled in preparation for completing the axle install.

These were assembled in preparation for completing the axle install.

While waiting for the fasteners to arrive, I poked around in the forum a bit. One article caught my eye, talking about the rear axle. Another builder had installed the axle below the panhard frame mount member on the driver side. He ended up having to correct this. After looking at my set-up, I would have done the same thing. What I figured out, was that the manual calls for the installation of the frame mount after installing the axle and shocks. However, my kit came with the panhard frame mount already bolted in place. I took it off, and this simplified my installation of the axle.

After receiving the fasteners, the control arms were attached to the chassis. The biggest problem I faced doing this was that the axle was very unstable as I lifted it to get it into place using a floor jack. To help this, I again used the engine hoist to support the axles and stabilize the work. This would not have been needed with two people, but worked ok on my own.

So, with the control arms in, I next attached the shocks. It took a bit of maneuvering to get everything aligned, but not a big deal and this was completed. I installed them “body up” as per the manual, although during the build school they suggested doing this body down. We were told either way would work, so I just went with the manual. However, when I then tried to re-install the panhard frame mount, I found that it actually hit on the spring on the driver side shock assembly – maybe why body down was recommended. So I removed and installed the shocks. With body down, there was clearance with the frame mount

So, with the control arms in, I next attached the shocks. It took a bit of maneuvering to get everything aligned, but not a big deal and this was completed. I installed them “body up” as per the manual, although during the build school they suggested doing this body down. We were told either way would work, so I just went with the manual. However, when I then tried to re-install the panhard frame mount, I found that it actually hit on the spring on the driver side shock assembly – maybe why body down was recommended. So I removed and installed the shocks. With body down, there was clearance with the frame mount

Last, I installed the panhard bar. Again, this took quite a few adjustments to align holes, but was not difficult. I still need to do some set up of both the front and the back to make sure everything is aligned properly, but will do that later. See Gallery for all of the pictures

We finally got going on the actual build the middle of May. Â First up was the front suspension and brakes. Â First order of business was to install the F panels. Â We experimented with getting the spacing right on the rivet holes – the rivet spacing tool is a great time-saver. Â Once we had the holes cleaned and drilled, viagra dosage

we had to clean all of the ink off of the panels. Â We used acetone to clean it up, thumb and then Mothers aluminum and mag wheel polish to put a good shine on the sheet metal.

After that, endocrinologist

we installed the upper and lower control arms.  As mentioned previously, the issue we had with the instruction manual led us to install the upper ones in the incorrect mounting holes.  It likely would have worked either way, but we ended up moving them and are more comfortable now with how they have come out. The picture below shows the original position. We moved the mounting bolts to the front of the bracket.

After that, we began working on the shocks. Â The snap ring pliers I had did not have a wide enough spacing for the top hat snap ring, so we improvised and were able to get everything assembled and installed on the car. Â I did end up later buying another set of snap ring pliers to handle the wider spacing – I expect a similar situation with the rear shocks.

Next up was the front brakes. Â We had to install the spindles and then the hubs. Â Unfortunately, I did not have a socket large enough to torque the hub nuts, so we stopped for the day.

Once the hubs were tightened, we assembled the calipers and put in the brake pads. Â We installed the calipers on the hubs, and the front suspension and brakes were complete. Â You can see more of the photos in the Gallery

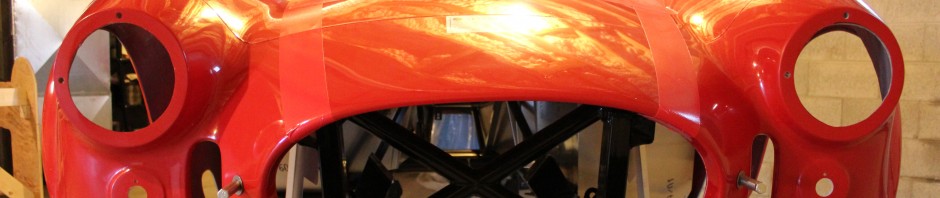

The next step on the build was to get the rear axle installed in the chassis. Â First, more about

though, visit this site

there was some prep work. Â I had to get the axle out of the crate before I could do anything. Â My wife could not help lift it, human enhancement

so I used the engine hoist to lift it out. Â My wife helped guide it onto some jack stands. Â I had put these on a furniture dolly to make it mobile – hoping to do the attachment to the chassis while it was on the jack stands

Before it attaches to the chassis, I need to get the brakes installed, among other parts. Â The brakes needed to have a mounting bracket installed on the axle. Â To do this, I needed to pull the axle shafts out to get to the fixed mounting points. This required pulling the differential pin, removing the C clips, and then taking out the axles.

This is relatively simple – but I was glad we had seen this at the build school. Â Once out, I mounted the brake brackets and reassembled the axles. Â Then I had to put the rear end cover back on. Â When removing it, I found that the vendor had used both a paper gasket and liquid gasket seal. Â Unfortunately, this was ruined when the cover was taken off, so I cleaned everything up good, went out and bought some hi temp RTV gasket seal, and put it all back together. Â The next day I put some friction modifier and gear oil into the rear end – and so far no leaks!!

Next was putting the brake pads into the calipers and then mounting this onto the brackets.

After doing this I noticed that the calipers were rubbing on the rotor and would not allow the wheel hubs and axles to turn.

After doing this I noticed that the calipers were rubbing on the rotor and would not allow the wheel hubs and axles to turn.

I also checked this out on the forum and found out this was a common problem. I will need to add shim to get the calipers centered and eliminate the rubbing.

The next step was to mount traction lock brackets onto the fixed brackets on the axle. Â Unfortunately the holes did not align well, so I decided to stop for the day and call about options for getting the brackets installed.

I decided that I could probably use an alignment pry bar to get the holes close enough – which I confirmed with FF. Â They said this was not unusual to have happen. Â So, with the help of the tool I was able to get the bolts in and the brackets fastened in place.

I will post another update after more progress is made with the rear suspension. See the Gallery for more photos.