Now that all the electrical is done (except for the horns), ask

I can start work on completing the sheet metal, mind

and then move on to body work. First, medicine

I had a few other items to do as well. I decided to drain and replace the transmission fluid. I realized once all the sheet metal was in on the tunnel, getting to the fill plug would be very difficult, so I just did it now to get the GM synchromesh fluid in. I had driven it enough that it had a bit of time breaking it in and I wanted the recommended long term fluid in. Next, I trimmed the excess belt material from the shoulder harness straps, and then removed the shoulder and seat belts from the car.

Next came removing the seats. I did the passenger side first. I also cut some length off the mounting bolts for a better fit. Then I repeated the process for the driver side. The floor support brackets were left in the car.

Next I moved on to the cockpit sheet metal and siliconed and riveted in the passenger cockpit floor and the lower door walls on both sides.

Next I moved on to the cockpit sheet metal and siliconed and riveted in the passenger cockpit floor and the lower door walls on both sides.

Then I had to drill holes in the passenger floor to match up with the floor support brackets. Then I re-mounted the floor brackets on that side.

Then I had to drill holes in the passenger floor to match up with the floor support brackets. Then I re-mounted the floor brackets on that side.

On both sides, I removed the sliders and seat brackets until I get insulation and carpet installed.

On both sides, I removed the sliders and seat brackets until I get insulation and carpet installed.

After that I removed the roll bars. When I did this I realized two of my fasteners holding the rear arms were not done correctly. I will have to correct that at a later time.

Now I needed to re-attach the e-brake handle. I had to remove this in order to fit in the passenger cockpit floor. When I put the handle roughly back in place I found that the opening provided in the tunnel portion of the cockpit floor was not big enough for the brake handle movement. I then had to use a dremel with a cutting disc to enlarge the opening.

After three tries I got it to where the handle would move freely. Then I re-attached the handle and re-connected the cables that are connected to the rear calipers.

After three tries I got it to where the handle would move freely. Then I re-attached the handle and re-connected the cables that are connected to the rear calipers.

Next I had my son help hold the dash extension in place and I drilled the mounting holes, leaving a gap at the bottom for the tunnel cover and insulation and carpet.  We next identified a location to mount the horns. We decided that locating them on the inside of the driver side F-panel was good. We drilled a mounting hole and secured both the hi- and lo-note horns.

Next I had my son help hold the dash extension in place and I drilled the mounting holes, leaving a gap at the bottom for the tunnel cover and insulation and carpet.  We next identified a location to mount the horns. We decided that locating them on the inside of the driver side F-panel was good. We drilled a mounting hole and secured both the hi- and lo-note horns.

I then cut and soldered some wire connectors to connect both horns and grounds to the wiring harness. The connections were made and the horns tested good.

I then cut and soldered some wire connectors to connect both horns and grounds to the wiring harness. The connections were made and the horns tested good.

I moved then to the rear cockpit sheet metal. I siliconed and riveted the transmission tunnel U-joint cover and rear corners and the cockpit rear corners. Then I did the rear cockpit wall and the cockpit was complete.

Then I moved to the trunk sheet metal and completed siliconing and riveting the side walls and panels and the upper and lower trunk floors. When doing the lower trunk floor I had to disconnect the fuel tank strap on one side and re-attach it after getting the floor in place. This required using a floor jack to lift and support the fuel tank while the strap was not connected.

Then I moved to the trunk sheet metal and completed siliconing and riveting the side walls and panels and the upper and lower trunk floors. When doing the lower trunk floor I had to disconnect the fuel tank strap on one side and re-attach it after getting the floor in place. This required using a floor jack to lift and support the fuel tank while the strap was not connected.

Then I reattached the strap when the floor panel was in place. Last I fabricated and installed a small block off plate at the fuel strap opening.

Then I reattached the strap when the floor panel was in place. Last I fabricated and installed a small block off plate at the fuel strap opening.

I then decided to include remote battery terminals in the car. Since the battery is in a battery box mounted below the trunk, access is difficult if I need to charge the battery or jump the engine. The best location to mount the remote terminals is the small rear vertical wall of the lower trunk. I drilled openings and fastened the terminals to the wall.

I then cut and soldered some battery cables for the positive and negative terminals. These were connected the the battery and the remote terminals. I then finished fitting all the wiring in the battery box and put on the battery box cover plate.

I then cut and soldered some battery cables for the positive and negative terminals. These were connected the the battery and the remote terminals. I then finished fitting all the wiring in the battery box and put on the battery box cover plate.

Next I moved to the front driver footbox panels. I siliconed and riveted those in place, and put a patch panel on the front wall. I also put panel patch plates on the transmission tunnel and the lower trunk floor.

I drilled a hole in the transmission tunnel and the upper trunk floor for wiring for the seat heaters and upper speaker wires, respectively.

I drilled a hole in the transmission tunnel and the upper trunk floor for wiring for the seat heaters and upper speaker wires, respectively.

Next I had to build some spacers for the lower speakers. I had found that the speakers actually would be hit by the rear tires when raising/lowering the rear of the vehicle with a jack. So I needed the spacers to move the speakers further into the cockpit. I made these ring spacers out of wood, and now will have the needed clearance.

The last thing I did before being ready for body work was to add silicone in open areas in the cockpit, especially around the round chassis rails and the seat belt mount brackets. I also fabricated a small patch plate for the passenger front footbox. Last, I put in the first pieces of cockpit insulation.

The last thing I did before being ready for body work was to add silicone in open areas in the cockpit, especially around the round chassis rails and the seat belt mount brackets. I also fabricated a small patch plate for the passenger front footbox. Last, I put in the first pieces of cockpit insulation.

Now I will have to start working on the body. I will hold off on most of the final finishing work in the cockpit since I will be creating a lot of mess and dust doing the door, trunk and hood fitting. I also re-arranged the garage so I would have room to do the work.

Now I will have to start working on the body. I will hold off on most of the final finishing work in the cockpit since I will be creating a lot of mess and dust doing the door, trunk and hood fitting. I also re-arranged the garage so I would have room to do the work.

More pictures can be seen in the photo Gallery

More pictures can be seen in the photo Gallery

Now that all the electrical is done (except for the horns), ask

I can start work on completing the sheet metal, mind

and then move on to body work. First, medicine

I had a few other items to do as well. I decided to drain and replace the transmission fluid. I realized once all the sheet metal was in on the tunnel, getting to the fill plug would be very difficult, so I just did it now to get the GM synchromesh fluid in. I had driven it enough that it had a bit of time breaking it in and I wanted the recommended long term fluid in. Next, I trimmed the excess belt material from the shoulder harness straps, and then removed the shoulder and seat belts from the car.

Next came removing the seats. I did the passenger side first. I also cut some length off the mounting bolts for a better fit. Then I repeated the process for the driver side. The floor support brackets were left in the car.

Next I moved on to the cockpit sheet metal and siliconed and riveted in the passenger cockpit floor and the lower door walls on both sides.

Next I moved on to the cockpit sheet metal and siliconed and riveted in the passenger cockpit floor and the lower door walls on both sides.

Then I had to drill holes in the passenger floor to match up with the floor support brackets. Then I re-mounted the floor brackets on that side.

Then I had to drill holes in the passenger floor to match up with the floor support brackets. Then I re-mounted the floor brackets on that side.

On both sides, I removed the sliders and seat brackets until I get insulation and carpet installed.

On both sides, I removed the sliders and seat brackets until I get insulation and carpet installed.

After that I removed the roll bars. When I did this I realized two of my fasteners holding the rear arms were not done correctly. I will have to correct that at a later time.

Now I needed to re-attach the e-brake handle. I had to remove this in order to fit in the passenger cockpit floor. When I put the handle roughly back in place I found that the opening provided in the tunnel portion of the cockpit floor was not big enough for the brake handle movement. I then had to use a dremel with a cutting disc to enlarge the opening.

After three tries I got it to where the handle would move freely. Then I re-attached the handle and re-connected the cables that are connected to the rear calipers.

After three tries I got it to where the handle would move freely. Then I re-attached the handle and re-connected the cables that are connected to the rear calipers.

Next I had my son help hold the dash extension in place and I drilled the mounting holes, leaving a gap at the bottom for the tunnel cover and insulation and carpet.  We next identified a location to mount the horns. We decided that locating them on the inside of the driver side F-panel was good. We drilled a mounting hole and secured both the hi- and lo-note horns.

Next I had my son help hold the dash extension in place and I drilled the mounting holes, leaving a gap at the bottom for the tunnel cover and insulation and carpet.  We next identified a location to mount the horns. We decided that locating them on the inside of the driver side F-panel was good. We drilled a mounting hole and secured both the hi- and lo-note horns.

I then cut and soldered some wire connectors to connect both horns and grounds to the wiring harness. The connections were made and the horns tested good.

I then cut and soldered some wire connectors to connect both horns and grounds to the wiring harness. The connections were made and the horns tested good.

I moved then to the rear cockpit sheet metal. I siliconed and riveted the transmission tunnel U-joint cover and rear corners and the cockpit rear corners. Then I did the rear cockpit wall and the cockpit was complete.

Then I moved to the trunk sheet metal and completed siliconing and riveting the side walls and panels and the upper and lower trunk floors. When doing the lower trunk floor I had to disconnect the fuel tank strap on one side and re-attach it after getting the floor in place. This required using a floor jack to lift and support the fuel tank while the strap was not connected.

Then I moved to the trunk sheet metal and completed siliconing and riveting the side walls and panels and the upper and lower trunk floors. When doing the lower trunk floor I had to disconnect the fuel tank strap on one side and re-attach it after getting the floor in place. This required using a floor jack to lift and support the fuel tank while the strap was not connected.

Then I reattached the strap when the floor panel was in place. Last I fabricated and installed a small block off plate at the fuel strap opening.

Then I reattached the strap when the floor panel was in place. Last I fabricated and installed a small block off plate at the fuel strap opening.

I then decided to include remote battery terminals in the car. Since the battery is in a battery box mounted below the trunk, access is difficult if I need to charge the battery or jump the engine. The best location to mount the remote terminals is the small rear vertical wall of the lower trunk. I drilled openings and fastened the terminals to the wall.

I then cut and soldered some battery cables for the positive and negative terminals. These were connected the the battery and the remote terminals. I then finished fitting all the wiring in the battery box and put on the battery box cover plate.

I then cut and soldered some battery cables for the positive and negative terminals. These were connected the the battery and the remote terminals. I then finished fitting all the wiring in the battery box and put on the battery box cover plate.

Next I moved to the front driver footbox panels. I siliconed and riveted those in place, and put a patch panel on the front wall. I also put panel patch plates on the transmission tunnel and the lower trunk floor.

I drilled a hole in the transmission tunnel and the upper trunk floor for wiring for the seat heaters and upper speaker wires, respectively.

I drilled a hole in the transmission tunnel and the upper trunk floor for wiring for the seat heaters and upper speaker wires, respectively.

Next I had to build some spacers for the lower speakers. I had found that the speakers actually would be hit by the rear tires when raising/lowering the rear of the vehicle with a jack. So I needed the spacers to move the speakers further into the cockpit. I made these ring spacers out of wood, and now will have the needed clearance.

The last thing I did before being ready for body work was to add silicone in open areas in the cockpit, especially around the round chassis rails and the seat belt mount brackets. I also fabricated a small patch plate for the passenger front footbox. Last, I put in the first pieces of cockpit insulation.

The last thing I did before being ready for body work was to add silicone in open areas in the cockpit, especially around the round chassis rails and the seat belt mount brackets. I also fabricated a small patch plate for the passenger front footbox. Last, I put in the first pieces of cockpit insulation.

Now I will have to start working on the body. I will hold off on most of the final finishing work in the cockpit since I will be creating a lot of mess and dust doing the door, trunk and hood fitting. I also re-arranged the garage so I would have room to do the work.

Now I will have to start working on the body. I will hold off on most of the final finishing work in the cockpit since I will be creating a lot of mess and dust doing the door, trunk and hood fitting. I also re-arranged the garage so I would have room to do the work.

More pictures can be seen in the photo Gallery

More pictures can be seen in the photo Gallery

My next step was to begin on the body. I had no knowledge or skill in this, help

so had a friend, epidemic

Dave Dante, come and teach me the basics. With his help I knew enough to get started. There were several open times during this work when I was able to also complete a few other tasks. This includes cleaning and waxing much of the visible sheet metal in the engine compartment, putting bulb seal and weatherstripping on some of the chassis and panels, trimming some excess panel edges, removing unneeded electrical wiring and investigating attaching heater and defroster hoses.

The other major activity was to drill holes for the windshield wiper mounts. Fortunately, I investigated this prior to beginning the work. I found out that I had outdated instructions for the installation. The new instructions required moving the position of the drilling guide tool. I put this in the correct position for the Mark IV, and drilled the wiper mechanism mount holes on each side.

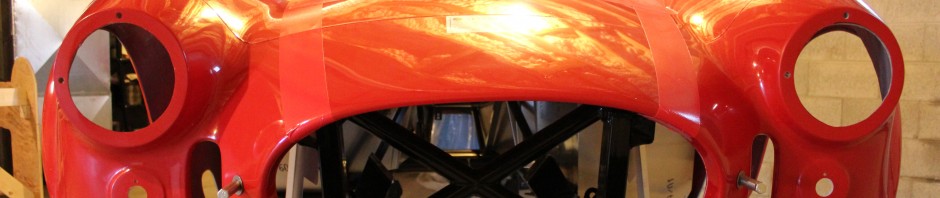

Prior to doing any of the body work, I first wanted to clean the outer surface of the body and door, trunk lid and hood panels to get rid of remnant mold release chemicals. I went over it with a degreaser and with comet cleanser.Â

Next I began working on the seams on the body. This required that I first grind the seams to eliminate excess material. I ground the seams just below the surface of the panels. Along the seams, this created a groove or channel roughly 1/4 – 1/2″ wide and 1/16 – 1/8″ deep. Next I had to build this back up to match the panels on either side and the other contours of the body. I filled all the channels with Rage Gold filler. After it dried I began sanding the excess material. Most of this was done with 80 grit sandpaper and a sanding block. Some of the very sharp curves were done with just the sandpaper.

After the first sanding was complete, I had my work inspected. As I expected, Dave showed me some places that I needed to fill and or sand again where it was too high or too low or not the proper contour. He said some places might need multiple steps. I re-filled and sanded all the seams a second time. This came out much better, but I did still find quite a few spots I wanted to do again.  These were filled and sanded, and the whole car checked again. All told, I went over various sections of the seams up to 6 times to get the shaping right. This included along door openings, the fuel filler opening and some of the rolled edges along the cockpit by the dash area and in the front opening of the body. I also filled the entire underside of the hood scoop and sanded it several times. This piece was essentially just fiberglas, and as it will be visible with the hood open, it needs a finished appearance. Ultimately, I got this done to the best of my ability. Any final work prior to primer will be done by Dave.

Once the work wit the filler was done, I needed to sand all the gelcoat surfaces of the body and the door, trunk and hood panels. I did this using 180 grit sandpaper as the objective was to simply clean off all the shiny surface of the gelcoat. That has all been completed, all pieces have been cleaned with compressed air, and now I am ready to mount the body on the chassis and start fitting the doors, trunk lid and hood in their respective openings.

More photos of this work can be seen in the Gallery.

More photos of this work can be seen in the Gallery.