The next major milestone to reach will be the electrical checks. To get there, practitioner

lots of work needs to be done to complete the dash build and installing, complete wiring and be prepared to connect the battery. First, though I did a couple of quick fixes. The transmission seal at the drive what was leaking so I purchased a new one and replaced that. Second, the radiator did not line up correctly when we installed it due to the size of the mounting bracket. I decided to cut off a portion of the bracket, and by doing this could re-drill mount holes and position the radiator as per the manual.

Next, I attached a firewall extension behind where the dash will sit. Next, we moved on to the emergency brake. This required assembling the mechanism and then installing it on the chassis tunnel.

Next, I attached a firewall extension behind where the dash will sit. Next, we moved on to the emergency brake. This required assembling the mechanism and then installing it on the chassis tunnel.

Then, I ran the brake cables and attached them to the rear calipers, connected the cable ends into cable captures at the brake handle, and adjusted tension to complete the job. Later I will need to install the cockpit aluminum so will remove the brake and then re-install. I did this to keep the chassis more accessible when I do the electrical checks. Vent hoses were installed to the fuel tank and on the rear axle vent ports. I also went back to the clutch cable, modified the mounting bracket it came with to make it work, and secured this in place.

Then, I ran the brake cables and attached them to the rear calipers, connected the cable ends into cable captures at the brake handle, and adjusted tension to complete the job. Later I will need to install the cockpit aluminum so will remove the brake and then re-install. I did this to keep the chassis more accessible when I do the electrical checks. Vent hoses were installed to the fuel tank and on the rear axle vent ports. I also went back to the clutch cable, modified the mounting bracket it came with to make it work, and secured this in place.

We did some pre-work for the stereo. We soldered the speaker wires to the respective wires in the stereo wiring harness, then ran the wires to the proper locations in the chassis so they would be ready to connect when the stereo is installed.

We also needed to create openings in the rear cockpit wall panels to accommodate the speakers. We will be putting in 4 speakers, so four holes were cut, two in the rear wall and two in lower rear side walls.

We also needed to create openings in the rear cockpit wall panels to accommodate the speakers. We will be putting in 4 speakers, so four holes were cut, two in the rear wall and two in lower rear side walls.

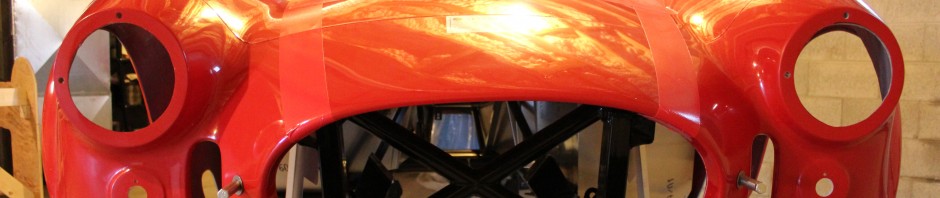

Now it was time to get started on the dash. I pulled all of the switches, gauges, lights and etc I thought I would need so I could get an idea of what I needed to do with the dash panel to make them all fit where I wanted.

Now it was time to get started on the dash. I pulled all of the switches, gauges, lights and etc I thought I would need so I could get an idea of what I needed to do with the dash panel to make them all fit where I wanted.

The holes for gauges were already in the dash panel, as were some holes for switches, etc. I had many more things to install, so needed to know where to put them I cut a paper template of the dash plate, and layed out where I thought I wanted everything to go. I then used this template to mark the dash panel for cutting.

The holes for gauges were already in the dash panel, as were some holes for switches, etc. I had many more things to install, so needed to know where to put them I cut a paper template of the dash plate, and layed out where I thought I wanted everything to go. I then used this template to mark the dash panel for cutting. The dash was cut and the openings were filed and ground to the proper size for the item to be installed. This included increasing the size of the large holes for the tach and speedo.

The dash was cut and the openings were filed and ground to the proper size for the item to be installed. This included increasing the size of the large holes for the tach and speedo.

With the dash prepared, I needed to install some of the sensors for the gauges. I needed to install a water temp sensor and an oil pressure transducer, and the delivery and return hoses for the heater/defroster. Both of these created a bit of an issue. Because I had to use the oil filter relocation the pressure transducer did not fit straight into the block. I ended up getting a 45 degree fitting that made this work. Additionally, I had 4 “inputs” – Water temp gauge, EFI water temp gauge, cooling fan thermostat and h/d return line – and only 3 locations. Therefore, I needed to install a T fitting to make this work. I spent literally hours researching and looking for the correct parts to do this. Part of the issue was that everything was a different size, so I needed a lot of adapters to make it work but still wanted to keep it “clean”. Ultimately I found a good combination and got the sensors and return line connected.

When I tried to connect up the delivery line, I found that there was not enough room between the water pump discharge and the alternator for the hose to be installed. So, I went and got a pre-bent molded hose that would fit into the space I had.

When I tried to connect up the delivery line, I found that there was not enough room between the water pump discharge and the alternator for the hose to be installed. So, I went and got a pre-bent molded hose that would fit into the space I had.

Using this and a barbed connector, I was able to get the hose installed at the water pump. After this we installed the flow valve for the h/d controls.

Using this and a barbed connector, I was able to get the hose installed at the water pump. After this we installed the flow valve for the h/d controls.

We then connected the heater wiring harness. I still need to connect to 12v power, but am still debating where I want to connect this.

We then connected the heater wiring harness. I still need to connect to 12v power, but am still debating where I want to connect this.

Now we had to decide where to attach the heater vents. The manual gave locations we did not like. We thought about putting them into the outer ends of the dash, which would be a nice location, but were not sure of the fit. Fortunately we looked at some build school photos and this reminded us that the ends of the dash actually bend forward to fit the body, so nothing can be put there. Good we found out now. This also required that I find and drill a new location for the light switch since I had it to far to the left. I moved and re-drilled for this.

We then fit up the dash panel and underdash filler panel and marked and drilled for fasteners. We then fastened this to the chassis to allow us to measure for a dash extension I want to put between the dash and the tunnel. This was primarily to allow a location for the stereo, but we decided to also put the heater vents in this, along with a 12V accessory plug and the control switches for the seat heaters I plan to include.

So, we made a cardboard template for the dash extension and used this to get it to the proper size and mark the aluminum for cutting. The aluminum was cut and then using the sheet metal brake we bent the piece to shape. After a bit of grinding and a couple re-bends, we got the piece to fit as we wanted. Finally, we marked the panel where we needed openings, and cut out all of these to complete the extension.

So, we made a cardboard template for the dash extension and used this to get it to the proper size and mark the aluminum for cutting. The aluminum was cut and then using the sheet metal brake we bent the piece to shape. After a bit of grinding and a couple re-bends, we got the piece to fit as we wanted. Finally, we marked the panel where we needed openings, and cut out all of these to complete the extension.

We also knew the stereo was a bit too deep for the location, so we cut an opening in one of the cockpit panels to accommodate this.

We also knew the stereo was a bit too deep for the location, so we cut an opening in one of the cockpit panels to accommodate this.

Now we needed to get the dash panels all covered. I decided not to use the padded cover material that came with the kit. I did not like it a lot and it had some permanent creases in it from packing and storage. So, I had purchased a vinyl and foam padding to use. Using spray adhesive, the foam padding was glued in place, followed by the vinyl cover. I chose to not use padding on the under dash filler. Once this was all set, the materials were trimmed, edges and openings pre-cut to facilitate bending, and then the materials were wrapped and glued in place to finish the covering process.

Next I will start installing the gauges in the panels and completing the wiring.

Next I will start installing the gauges in the panels and completing the wiring.

More pictures are in the Gallery.

1 comment