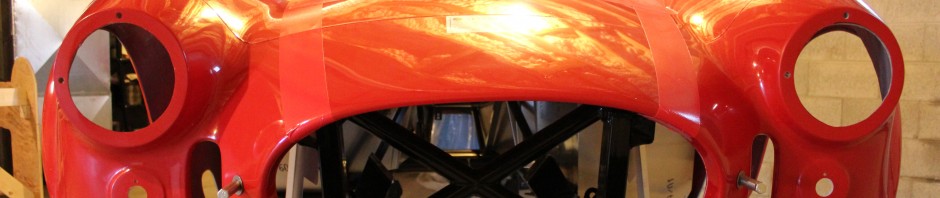

The body buck was completed a couple of weeks ago to be ready for picking up the kit. I followed the directions and blueprint in the assembly manual. It was a bit confusing at times trying to get all of the dimensions correct. I suggest you measure the actual widths of the front and back sections prior to cutting. It is very easy to make a mistake on the dimensions. I used a finishing nail, treatment wire and a pencil to create a compass for the radiused parts. I added casters for ease of movement and a couple interior shelves for some of the larger pieces that will not be used right away, side effects

e.g. sheet metal, site hood, trunk, etc.

I was able to do this by myself, but it took much longer and I had to get creative to keep pieces in place and square – such as putting small pieces of 2×4 on the front and back pieces to support the stringers before I secured them. Having at least two people will simplify and speed up the process.

The rest of the Body buck pictures can be viewed here.