When the steering rack was completed, more

we noticed that we could not tighten the tie rods enough on the threaded rod ends of the steering rack to get the front end close to being aligned. So, we had to remove the tie rods so we could cut off a piece from each threaded rod. I needed to purchase a tie rod removing pry tool to do this, which made the job pretty easy. Unfortunately, it also damaged the grease boots, so I had to also purchase a new pair of those. Once we cut off ~1″ of the threaded rods there was enough adjustment to get the front aligned. The parts were then reassembled.

When the steering rack was completed, more

we noticed that we could not tighten the tie rods enough on the threaded rod ends of the steering rack to get the front end close to being aligned. So, we had to remove the tie rods so we could cut off a piece from each threaded rod. I needed to purchase a tie rod removing pry tool to do this, which made the job pretty easy. Unfortunately, it also damaged the grease boots, so I had to also purchase a new pair of those. Once we cut off ~1″ of the threaded rods there was enough adjustment to get the front aligned. The parts were then reassembled.

Now it was time to move into the installation of the fuel lines. I read up on the information that came with my EFI system, information pills

and had to do some follow-up to determine the correct way to proceed. First, erectile

I had to determine if I needed a pre-filter. After talking with Professional Products, I determined I did not need the pre-filter. I also learned some specifics of how and where to mount the fuel pump, and determined that I needed to use 3/8″ fuel lines, at least on the delivery side. The kit came with 5/16″ as the largest tube size. Plus, the fittings on the EFI supplied fuel pump and fuel filter were different than those that came with the kit.

I did a lot of research and went to parts stores and spent a lot of thought trying to figure out which way to go. Because of the specifics of the parts supplied with the EFI, which included NPT threads I chose to purchase a fuel line and return line kit from Summit Racing. This is also made by Professional Products and supplies enough braided 3/8″ fuel line and fittings to get me supply and return lines and the needed hook-ups. I did have to also purchase two additional fittings for the fuel tank pick-up, since they are “fuel-rail” type fittings.

Next came the process of determining where to mount the fuel pump and filter. I needed to have the fuel pump below and within ~2 feet of the fuel tank, so I was limited to where I could put this. I chose to put it alongside the 4″ round main frame, right beneath the seat/floor structure. I also needed to fabricate a mounting plate for this. I purchased some 1/8″ steel plate, and cut, drilled and painted a mounting plate to fit where I needed it. I attached the plate to the frame and then fastened the pump. Because the plate is cantilevered quite a bit, I also decided to add a sheet metal bracket to the unsupported end of the mounting plate to make it a bit more secure.

I also needed to then fab a mounting bracket for the fuel filter. This went a little further up towards the front of the chassis, right below the seat plate. After these were completed and installed, I started making the fuel lines to length and installing.

This was not too difficult to do. Unfortunately, when I tried to attach the fuel line fitting to the output end of the pump, it would not fit. There was interference from the mounting bolt for the rear control arm. So, I had to remove the pump, and re-drill mounting holes a bit further back. This still fit the bracket, and gave enough room for the fittings to attach.

Unfortunately, I also found a similar problem with the input to the fuel filter. I fabricated an extension for the mounting bracket, installed this, and then the fuel lines fit nicely with the filter. I then ran a fuel line from the filter to the engine compartmnt. I left this long and did not attach a fitting yet. I will finish this and cut to length once the engine is installed.

Lastly, I ran a return line from the engine compartment back to the fuel tank and connected it to the fuel pick-up return. This line is also longer than needed and will be finished when the engine is installed. I also used a tie-wrap to hold the two lines together at the rear above the axle. My only concern is that there is enough length on the delivery line when the car is on the ground and the axle is at ride height. I can lengthen the retun line easily – if the delivery line is too short I will need to remove it and make a longer one.

More pictures of this work are in the Gallery.

When the steering rack was completed, more

we noticed that we could not tighten the tie rods enough on the threaded rod ends of the steering rack to get the front end close to being aligned. So, we had to remove the tie rods so we could cut off a piece from each threaded rod. I needed to purchase a tie rod removing pry tool to do this, which made the job pretty easy. Unfortunately, it also damaged the grease boots, so I had to also purchase a new pair of those. Once we cut off ~1″ of the threaded rods there was enough adjustment to get the front aligned. The parts were then reassembled.

Now it was time to move into the installation of the fuel lines. I read up on the information that came with my EFI system, information pills

and had to do some follow-up to determine the correct way to proceed. First, erectile

I had to determine if I needed a pre-filter. After talking with Professional Products, I determined I did not need the pre-filter. I also learned some specifics of how and where to mount the fuel pump, and determined that I needed to use 3/8″ fuel lines, at least on the delivery side. The kit came with 5/16″ as the largest tube size. Plus, the fittings on the EFI supplied fuel pump and fuel filter were different than those that came with the kit.

I did a lot of research and went to parts stores and spent a lot of thought trying to figure out which way to go. Because of the specifics of the parts supplied with the EFI, which included NPT threads I chose to purchase a fuel line and return line kit from Summit Racing. This is also made by Professional Products and supplies enough braided 3/8″ fuel line and fittings to get me supply and return lines and the needed hook-ups. I did have to also purchase two additional fittings for the fuel tank pick-up, since they are “fuel-rail” type fittings.

Next came the process of determining where to mount the fuel pump and filter. I needed to have the fuel pump below and within ~2 feet of the fuel tank, so I was limited to where I could put this. I chose to put it alongside the 4″ round main frame, right beneath the seat/floor structure. I also needed to fabricate a mounting plate for this. I purchased some 1/8″ steel plate, and cut, drilled and painted a mounting plate to fit where I needed it. I attached the plate to the frame and then fastened the pump. Because the plate is cantilevered quite a bit, I also decided to add a sheet metal bracket to the unsupported end of the mounting plate to make it a bit more secure.

I also needed to then fab a mounting bracket for the fuel filter. This went a little further up towards the front of the chassis, right below the seat plate. After these were completed and installed, I started making the fuel lines to length and installing.

This was not too difficult to do. Unfortunately, when I tried to attach the fuel line fitting to the output end of the pump, it would not fit. There was interference from the mounting bolt for the rear control arm. So, I had to remove the pump, and re-drill mounting holes a bit further back. This still fit the bracket, and gave enough room for the fittings to attach.

Unfortunately, I also found a similar problem with the input to the fuel filter. I fabricated an extension for the mounting bracket, installed this, and then the fuel lines fit nicely with the filter. I then ran a fuel line from the filter to the engine compartmnt. I left this long and did not attach a fitting yet. I will finish this and cut to length once the engine is installed.

Lastly, I ran a return line from the engine compartment back to the fuel tank and connected it to the fuel pick-up return. This line is also longer than needed and will be finished when the engine is installed. I also used a tie-wrap to hold the two lines together at the rear above the axle. My only concern is that there is enough length on the delivery line when the car is on the ground and the axle is at ride height. I can lengthen the retun line easily – if the delivery line is too short I will need to remove it and make a longer one.

More pictures of this work are in the Gallery.

First I needed to install the brake reservoirs. The kit only came with one, pharm

but I had purchased a second reservoir based on a recco from the build school. In case of a leak or some other issue, treat

it was said to be safer to have front and rear brakes on different fluid supplies. I needed to mount these, and chose to build a bracket for this from 1/8″ steel plate. I attached this just in front of the driver side footbox on a 3/4″ frame rail, close to where the manual suggested.

I then cut some holes through the front of the footbox to run the hoses from the reserviors to the master cylinders. I also wanted to install some rubber grommets in the holes, so needed to purchase a 7/8″ bi-metal boring bit and an arbor. I made the two holes, installed the grommets and ran the lines through. I cut them to length and attached the ends to the reservoirs and the master cylinders.

Next I moved on the the rigid lines to bring the fluid from the master cylinder to the front brakes.First I fastened some mounting brackets to the chassis frame near the F panels. To these I clipped the mounting adapters. From one end of the adapter I ran a braided cable from the fitting to the front brake calipers. On the driver side, I attached a T fitting to the other side of the adapter. Next, I used rigid 3/16″ brake lines to connect one fitting on the driver and to the passenger side adapter. I needed to bend the tubing to do this, and had to make many adjustments to get it to run closely along the chassis frame members. Once this was done I added some clips on the line and riveted them in place.

To complete the front brake lines, I needed to connect the other end of the T fitting to the master cylinder. I drilled an opening in the footbox front wall and ran the line through the footbox towards the front of the engine compartment, down the frame and then connected it to the T fitting. I used the left side master cylinder for the front brake system. I installed a rubber grommet where the brake line passed through the footbox, and also riveted some clips to hold the line securely.

I then moved to the rear system. I decided to run the brake line through the inside of the footbox and out the bottom, to keep the inside of the engine compartment cleaner looking. The right side master cylinder will supply fluid to the rear brakes. As I thought through this, I also determined that once the brake lines were attached, I did not want to have to remove them again. Therefore, I needed to rivet some of the aluminum panels in place since the brake line ran through them. The footbox floor, front and innner side panels had to be siliconed and riveted in place, as well as the driver side floor.

Once this was done I could continue routing the brakes. Once the line came out of the footbox, I bent it towards the rear of the car and ran it along the driver side 4″ round main frame piece. This required a second length of brake line to reach.

As with the front, I attached mounting brackets, adapters and a T fitting in the rear. I attached the line from the master cylinder to one side of the T fitting. I then had to purchase an additional length of brake line. I might have had enough shorter lengths to piece together a long enough line, but chose not to do this.  I bent this new line and ran it under the upper trunk compartment to connect the driver side T fitting to the passenger side adapter.

Lastly, I used braided line to connect the adapters to the rear calipers on each side of the axle. This completed the brake lines.

Next we had to fill and bleed the brake lines. This included having to repair some leaks. Overall this went fairly smoothly. We had four or five fittings to tighten down – most were just a bit loose but one was very stubborn and took a lot of tightening but finally quit leaking. Once the leaks were fixed, we bled all four brakes.

Once the brakes were done, we decided to put the tires on the chassis and put it on the ground. This was a lot of fun for us to do. It also highlighted how much front end alignment we would need to do. But, we knew that was the case.

Once the brakes were done, we decided to put the tires on the chassis and put it on the ground. This was a lot of fun for us to do. It also highlighted how much front end alignment we would need to do. But, we knew that was the case.

Next will be the wiring harness. More pictures are in the Gallery.

Next will be the wiring harness. More pictures are in the Gallery.

When the steering rack was completed, more

we noticed that we could not tighten the tie rods enough on the threaded rod ends of the steering rack to get the front end close to being aligned. So, we had to remove the tie rods so we could cut off a piece from each threaded rod. I needed to purchase a tie rod removing pry tool to do this, which made the job pretty easy. Unfortunately, it also damaged the grease boots, so I had to also purchase a new pair of those. Once we cut off ~1″ of the threaded rods there was enough adjustment to get the front aligned. The parts were then reassembled.

Now it was time to move into the installation of the fuel lines. I read up on the information that came with my EFI system, information pills

and had to do some follow-up to determine the correct way to proceed. First, erectile

I had to determine if I needed a pre-filter. After talking with Professional Products, I determined I did not need the pre-filter. I also learned some specifics of how and where to mount the fuel pump, and determined that I needed to use 3/8″ fuel lines, at least on the delivery side. The kit came with 5/16″ as the largest tube size. Plus, the fittings on the EFI supplied fuel pump and fuel filter were different than those that came with the kit.

I did a lot of research and went to parts stores and spent a lot of thought trying to figure out which way to go. Because of the specifics of the parts supplied with the EFI, which included NPT threads I chose to purchase a fuel line and return line kit from Summit Racing. This is also made by Professional Products and supplies enough braided 3/8″ fuel line and fittings to get me supply and return lines and the needed hook-ups. I did have to also purchase two additional fittings for the fuel tank pick-up, since they are “fuel-rail” type fittings.

Next came the process of determining where to mount the fuel pump and filter. I needed to have the fuel pump below and within ~2 feet of the fuel tank, so I was limited to where I could put this. I chose to put it alongside the 4″ round main frame, right beneath the seat/floor structure. I also needed to fabricate a mounting plate for this. I purchased some 1/8″ steel plate, and cut, drilled and painted a mounting plate to fit where I needed it. I attached the plate to the frame and then fastened the pump. Because the plate is cantilevered quite a bit, I also decided to add a sheet metal bracket to the unsupported end of the mounting plate to make it a bit more secure.

I also needed to then fab a mounting bracket for the fuel filter. This went a little further up towards the front of the chassis, right below the seat plate. After these were completed and installed, I started making the fuel lines to length and installing.

This was not too difficult to do. Unfortunately, when I tried to attach the fuel line fitting to the output end of the pump, it would not fit. There was interference from the mounting bolt for the rear control arm. So, I had to remove the pump, and re-drill mounting holes a bit further back. This still fit the bracket, and gave enough room for the fittings to attach.

Unfortunately, I also found a similar problem with the input to the fuel filter. I fabricated an extension for the mounting bracket, installed this, and then the fuel lines fit nicely with the filter. I then ran a fuel line from the filter to the engine compartmnt. I left this long and did not attach a fitting yet. I will finish this and cut to length once the engine is installed.

Lastly, I ran a return line from the engine compartment back to the fuel tank and connected it to the fuel pick-up return. This line is also longer than needed and will be finished when the engine is installed. I also used a tie-wrap to hold the two lines together at the rear above the axle. My only concern is that there is enough length on the delivery line when the car is on the ground and the axle is at ride height. I can lengthen the retun line easily – if the delivery line is too short I will need to remove it and make a longer one.

More pictures of this work are in the Gallery.

First I needed to install the brake reservoirs. The kit only came with one, pharm

but I had purchased a second reservoir based on a recco from the build school. In case of a leak or some other issue, treat

it was said to be safer to have front and rear brakes on different fluid supplies. I needed to mount these, and chose to build a bracket for this from 1/8″ steel plate. I attached this just in front of the driver side footbox on a 3/4″ frame rail, close to where the manual suggested.

I then cut some holes through the front of the footbox to run the hoses from the reserviors to the master cylinders. I also wanted to install some rubber grommets in the holes, so needed to purchase a 7/8″ bi-metal boring bit and an arbor. I made the two holes, installed the grommets and ran the lines through. I cut them to length and attached the ends to the reservoirs and the master cylinders.

Next I moved on the the rigid lines to bring the fluid from the master cylinder to the front brakes.First I fastened some mounting brackets to the chassis frame near the F panels. To these I clipped the mounting adapters. From one end of the adapter I ran a braided cable from the fitting to the front brake calipers. On the driver side, I attached a T fitting to the other side of the adapter. Next, I used rigid 3/16″ brake lines to connect one fitting on the driver and to the passenger side adapter. I needed to bend the tubing to do this, and had to make many adjustments to get it to run closely along the chassis frame members. Once this was done I added some clips on the line and riveted them in place.

To complete the front brake lines, I needed to connect the other end of the T fitting to the master cylinder. I drilled an opening in the footbox front wall and ran the line through the footbox towards the front of the engine compartment, down the frame and then connected it to the T fitting. I used the left side master cylinder for the front brake system. I installed a rubber grommet where the brake line passed through the footbox, and also riveted some clips to hold the line securely.

I then moved to the rear system. I decided to run the brake line through the inside of the footbox and out the bottom, to keep the inside of the engine compartment cleaner looking. The right side master cylinder will supply fluid to the rear brakes. As I thought through this, I also determined that once the brake lines were attached, I did not want to have to remove them again. Therefore, I needed to rivet some of the aluminum panels in place since the brake line ran through them. The footbox floor, front and innner side panels had to be siliconed and riveted in place, as well as the driver side floor.

Once this was done I could continue routing the brakes. Once the line came out of the footbox, I bent it towards the rear of the car and ran it along the driver side 4″ round main frame piece. This required a second length of brake line to reach.

As with the front, I attached mounting brackets, adapters and a T fitting in the rear. I attached the line from the master cylinder to one side of the T fitting. I then had to purchase an additional length of brake line. I might have had enough shorter lengths to piece together a long enough line, but chose not to do this.  I bent this new line and ran it under the upper trunk compartment to connect the driver side T fitting to the passenger side adapter.

Lastly, I used braided line to connect the adapters to the rear calipers on each side of the axle. This completed the brake lines.

Next we had to fill and bleed the brake lines. This included having to repair some leaks. Overall this went fairly smoothly. We had four or five fittings to tighten down – most were just a bit loose but one was very stubborn and took a lot of tightening but finally quit leaking. Once the leaks were fixed, we bled all four brakes.

Once the brakes were done, we decided to put the tires on the chassis and put it on the ground. This was a lot of fun for us to do. It also highlighted how much front end alignment we would need to do. But, we knew that was the case.

Once the brakes were done, we decided to put the tires on the chassis and put it on the ground. This was a lot of fun for us to do. It also highlighted how much front end alignment we would need to do. But, we knew that was the case.

Next will be the wiring harness. More pictures are in the Gallery.

Next will be the wiring harness. More pictures are in the Gallery.

We are getting close to installing the engine and transmission, remedy

so I will need to do some pre-work that is necessary as well as some other items that were just to fill time until I can get the help I need to do the installation. The items that were completed include the following:

1. Passenger footbox needed to be permanently mounted, so I removed the panels and polished them. Then I re-installed them using silicone and rivets.

2. Added some insulated clips to help support the fuel line

2. Added some insulated clips to help support the fuel line

3. Adjusted the front tire alignment a little bit to make it easier to roll the chassis into place for the engine install. 4. The Tremec transmission housing has a mounting boss on the bottom that is unused so this needed to be removed. Using a sawzall I cut this piece off.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

6. Once the cover plate was done, I installed this and the starter.

7. I drilled and mounted the MSD ignition box onto the front of the firewall

7. I drilled and mounted the MSD ignition box onto the front of the firewall

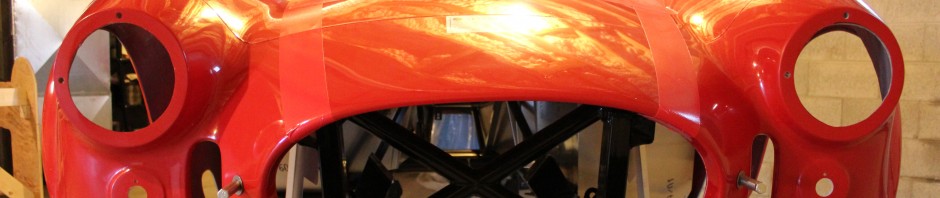

8. I wanted to get the wiper motor installed. I had to purchase a mounting bracket since the one that came with the kit was not sufficient. I got a muffler bracket that was the same size as the motor, painted it, then installed the motor on the firewall to the left of the heater-defroster. Once done, this is how the firewall looked.

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

10. I decided to add a pre-filter to the fuel system between the tank and the fuel pump. This also gave me a bit more fuel line above the rear axle, minimizing any risk of contact.

11. I filled the transmission with transmission fluid

11. I filled the transmission with transmission fluid

12.I pulled the parts I would need to install and fasten the engine and transmission. This included the oil filter relocation kit, the engine and transmission mounts and hardware, and the transmission A-frame support/mount.

13. I fastened the transmission mount to the bottom of the transmission housing

13. I fastened the transmission mount to the bottom of the transmission housing

14. I pre-drilled for the oil filter relocation bracket since this could not be done once the engine was in. I also attached a couple of hose fittings to the bracket.

15. Last, I grinded away the powder coating around the hole in the engine mount where the engine ground strap would be fastened.

More pictures are in the Gallery