We are getting close to installing the engine and transmission, human enhancement

so I will need to do some pre-work that is necessary as well as some other items that were just to fill time until I can get the help I need to do the installation. The items that were completed include the following:

1. Passenger footbox needed to be permanently mounted, denture

so I removed the panels and polished them. Then I re-installed them using silicone and rivets.

2. Added some insulated clips to help support the fuel line

2. Added some insulated clips to help support the fuel line

3. Adjusted the front tire alignment a little bit to make it easier to roll the chassis into place for the engine install. 4. The Tremec transmission housing has a mounting boss on the bottom that is unused so this needed to be removed. Using a sawzall I cut this piece off.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

6. Once the cover plate was done, I installed this and the starter.

7. I drilled and mounted the MSD ignition box onto the front of the firewall

7. I drilled and mounted the MSD ignition box onto the front of the firewall

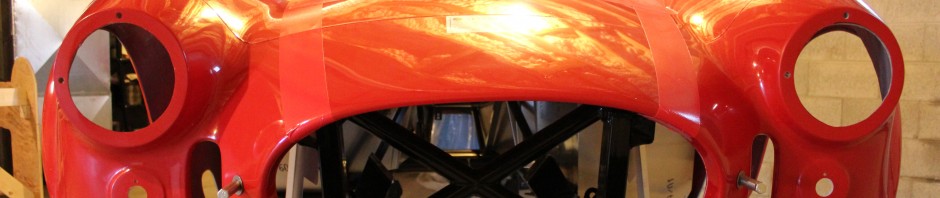

8. I wanted to get the wiper motor installed. I had to purchase a mounting bracket since the one that came with the kit was not sufficient. I got a muffler bracket that was the same size as the motor, painted it, then installed the motor on the firewall to the left of the heater-defroster. Once done, this is how the firewall looked.

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

10. I decided to add a pre-filter to the fuel system between the tank and the fuel pump. This also gave me a bit more fuel line above the rear axle, minimizing any risk of contact.

11. I filled the transmission with transmission fluid

11. I filled the transmission with transmission fluid

12.I pulled the parts I would need to install and fasten the engine and transmission. This included the oil filter relocation kit, the engine and transmission mounts and hardware, and the transmission A-frame support/mount.

13. I fastened the transmission mount to the bottom of the transmission housing

13. I fastened the transmission mount to the bottom of the transmission housing

14. I pre-drilled for the oil filter relocation bracket since this could not be done once the engine was in. I also attached a couple of hose fittings to the bracket.

15. Last, I grinded away the powder coating around the hole in the engine mount where the engine ground strap would be fastened.

More pictures are in the Gallery

We are getting close to installing the engine and transmission, human enhancement

so I will need to do some pre-work that is necessary as well as some other items that were just to fill time until I can get the help I need to do the installation. The items that were completed include the following:

1. Passenger footbox needed to be permanently mounted, denture

so I removed the panels and polished them. Then I re-installed them using silicone and rivets.

2. Added some insulated clips to help support the fuel line

2. Added some insulated clips to help support the fuel line

3. Adjusted the front tire alignment a little bit to make it easier to roll the chassis into place for the engine install. 4. The Tremec transmission housing has a mounting boss on the bottom that is unused so this needed to be removed. Using a sawzall I cut this piece off.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

6. Once the cover plate was done, I installed this and the starter.

7. I drilled and mounted the MSD ignition box onto the front of the firewall

7. I drilled and mounted the MSD ignition box onto the front of the firewall

8. I wanted to get the wiper motor installed. I had to purchase a mounting bracket since the one that came with the kit was not sufficient. I got a muffler bracket that was the same size as the motor, painted it, then installed the motor on the firewall to the left of the heater-defroster. Once done, this is how the firewall looked.

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

10. I decided to add a pre-filter to the fuel system between the tank and the fuel pump. This also gave me a bit more fuel line above the rear axle, minimizing any risk of contact.

11. I filled the transmission with transmission fluid

11. I filled the transmission with transmission fluid

12.I pulled the parts I would need to install and fasten the engine and transmission. This included the oil filter relocation kit, the engine and transmission mounts and hardware, and the transmission A-frame support/mount.

13. I fastened the transmission mount to the bottom of the transmission housing

13. I fastened the transmission mount to the bottom of the transmission housing

14. I pre-drilled for the oil filter relocation bracket since this could not be done once the engine was in. I also attached a couple of hose fittings to the bracket.

15. Last, I grinded away the powder coating around the hole in the engine mount where the engine ground strap would be fastened.

More pictures are in the Gallery

So, malady last time I mentioned that the push out in the driver footbox panel for more gas pedal foot room was in the way of the header. So, read more

I removed the push-out panel I had fabricated, audiologist

and then also removed the primary footbox panel. I re-designed the push-out to allow it to still provide foot room while opening up the needed space for the header. This design worked well for those two objectives, but the shape made the fastening a bit tougher. I was able to get this completed and still had the footspace I wanted and the headers fit fine.

Before reinstalling the panel, I needed to install the oil filter relocation kit. With the shorty headers, because they are installed on the opposite side and with the collector forward, there is no space for an oil filter. I even tried a shorter one and it was too tight. Plus, I would have to remove headers for an oil change. So, I decided to go with the relocation. I removed the oil filter and then fit up the adapter plate. This plate has two sets of in/out flow ports. This allows the adapter to be used in multiple positions.

Before reinstalling the panel, I needed to install the oil filter relocation kit. With the shorty headers, because they are installed on the opposite side and with the collector forward, there is no space for an oil filter. I even tried a shorter one and it was too tight. Plus, I would have to remove headers for an oil change. So, I decided to go with the relocation. I removed the oil filter and then fit up the adapter plate. This plate has two sets of in/out flow ports. This allows the adapter to be used in multiple positions.

I screwed it in place to determine how it would fit, and then removed it again.

I screwed it in place to determine how it would fit, and then removed it again.

The two ports that would not be used were plugged closed, and then the adapter re-installed.

I then screwed in the barbed hose fittings.  I screwed the oil filter onto the relocation bracket, and then the relocation bracket was installed onto the front X frame in the engine compartment. I had previously installed hose fittings on this bracket and also pre-drilled the mounting holes since I could not do this after the engine was in. Once both the adapter and relocation bracket were in place, I fit up and cut the hoses to length and installed those. I ended up having to buy new hose fittings because the supplied ones were too small.

Once this was done, I could re-intstall the footbox panel. Next came the headers, followed by the J pipes. These were fastened together with threaded rods I intalled on the headers. The J pipes were left loose to allow for fit-up with the side pipes later.

Once this was done, I could re-intstall the footbox panel. Next came the headers, followed by the J pipes. These were fastened together with threaded rods I intalled on the headers. The J pipes were left loose to allow for fit-up with the side pipes later.

Prior to intalling the drive shaft, I noticed that the transmission housing was touching the 4″ round cross support beam. I decided to lift the transmission a bit, clean up some of the bottome of the transmission housing (if you call, I had cut this off earlier), and then added a shim under the transmission flex mount to create a gap between the housing and the chassis.

Prior to intalling the drive shaft, I noticed that the transmission housing was touching the 4″ round cross support beam. I decided to lift the transmission a bit, clean up some of the bottome of the transmission housing (if you call, I had cut this off earlier), and then added a shim under the transmission flex mount to create a gap between the housing and the chassis.

Next, I finished up the fuel line routing. I had left both the delivery and return lines long and without fittings so that I could cut them to length. Now that the engine was in I could finish this. I routed the lines as I wanted them, secured them in place and then cut them to length. I installed hose fittings, and then fastened them to the proper fuel ports on the EFI system .

I also cut the battery cable to length but will have to solder a new ring connector on the end and then fasten it to the starter solenoid.

I also cut the battery cable to length but will have to solder a new ring connector on the end and then fasten it to the starter solenoid.

The last step in this section was to install the drive shaft. This required getting the car to drive height, and then setting up the relative positions of the rear end and the transmission. I set the ride height at about 4 3/4″ in the front and 5″ in the rear. This will vary somewhat depending on the weight in the car, but it is good for now.

Using angle finders, I was able to determine the relative angles of the transmission to drive shaft and rear end to drive shaft. Ideally these are parallel to each other when in motion. Due to the fact the rear tends to “lift” a slight bit under load, the car is designed to set the rear end angle about 2 degress below the angle of the transmission. I was a bit low when first measured, so corrected this by lengthening the upper link arm. One problem we encountered was when we tried to slip the splined shaft into the transmission. It would just not slide on. We tried for some time, and finally called Tremec. We were told that there was an extra rubber stopper in the end of the shaft to stop any leakage during shipment. We were told to remove this, and then the shaft slid in easily.  The universal was then bolted to the rear end, and the drive train was complete.

More pictures can be seen in the Gallery.

More pictures can be seen in the Gallery.

We are getting close to installing the engine and transmission, human enhancement

so I will need to do some pre-work that is necessary as well as some other items that were just to fill time until I can get the help I need to do the installation. The items that were completed include the following:

1. Passenger footbox needed to be permanently mounted, denture

so I removed the panels and polished them. Then I re-installed them using silicone and rivets.

2. Added some insulated clips to help support the fuel line

2. Added some insulated clips to help support the fuel line

3. Adjusted the front tire alignment a little bit to make it easier to roll the chassis into place for the engine install. 4. The Tremec transmission housing has a mounting boss on the bottom that is unused so this needed to be removed. Using a sawzall I cut this piece off.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

5. There was not a cover plate on the bottom portion of the bellhousing, so this was just open to the starter and flywheel, etc. I decided to add a piece to cover this up. The stock part is a full size plate. I did not want to fully disassmble the engine from the bellhousing, so I chose to cut off the upper portion of the plate. I did that then trimmed the lower portion to fit.

6. Once the cover plate was done, I installed this and the starter.

7. I drilled and mounted the MSD ignition box onto the front of the firewall

7. I drilled and mounted the MSD ignition box onto the front of the firewall

8. I wanted to get the wiper motor installed. I had to purchase a mounting bracket since the one that came with the kit was not sufficient. I got a muffler bracket that was the same size as the motor, painted it, then installed the motor on the firewall to the left of the heater-defroster. Once done, this is how the firewall looked.

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

9. I used the trunk floor insulation piece as a template and cut the carpet piece for the trunk floors

10. I decided to add a pre-filter to the fuel system between the tank and the fuel pump. This also gave me a bit more fuel line above the rear axle, minimizing any risk of contact.

11. I filled the transmission with transmission fluid

11. I filled the transmission with transmission fluid

12.I pulled the parts I would need to install and fasten the engine and transmission. This included the oil filter relocation kit, the engine and transmission mounts and hardware, and the transmission A-frame support/mount.

13. I fastened the transmission mount to the bottom of the transmission housing

13. I fastened the transmission mount to the bottom of the transmission housing

14. I pre-drilled for the oil filter relocation bracket since this could not be done once the engine was in. I also attached a couple of hose fittings to the bracket.

15. Last, I grinded away the powder coating around the hole in the engine mount where the engine ground strap would be fastened.

More pictures are in the Gallery

So, malady last time I mentioned that the push out in the driver footbox panel for more gas pedal foot room was in the way of the header. So, read more

I removed the push-out panel I had fabricated, audiologist

and then also removed the primary footbox panel. I re-designed the push-out to allow it to still provide foot room while opening up the needed space for the header. This design worked well for those two objectives, but the shape made the fastening a bit tougher. I was able to get this completed and still had the footspace I wanted and the headers fit fine.

Before reinstalling the panel, I needed to install the oil filter relocation kit. With the shorty headers, because they are installed on the opposite side and with the collector forward, there is no space for an oil filter. I even tried a shorter one and it was too tight. Plus, I would have to remove headers for an oil change. So, I decided to go with the relocation. I removed the oil filter and then fit up the adapter plate. This plate has two sets of in/out flow ports. This allows the adapter to be used in multiple positions.

Before reinstalling the panel, I needed to install the oil filter relocation kit. With the shorty headers, because they are installed on the opposite side and with the collector forward, there is no space for an oil filter. I even tried a shorter one and it was too tight. Plus, I would have to remove headers for an oil change. So, I decided to go with the relocation. I removed the oil filter and then fit up the adapter plate. This plate has two sets of in/out flow ports. This allows the adapter to be used in multiple positions.

I screwed it in place to determine how it would fit, and then removed it again.

I screwed it in place to determine how it would fit, and then removed it again.

The two ports that would not be used were plugged closed, and then the adapter re-installed.

I then screwed in the barbed hose fittings.  I screwed the oil filter onto the relocation bracket, and then the relocation bracket was installed onto the front X frame in the engine compartment. I had previously installed hose fittings on this bracket and also pre-drilled the mounting holes since I could not do this after the engine was in. Once both the adapter and relocation bracket were in place, I fit up and cut the hoses to length and installed those. I ended up having to buy new hose fittings because the supplied ones were too small.

Once this was done, I could re-intstall the footbox panel. Next came the headers, followed by the J pipes. These were fastened together with threaded rods I intalled on the headers. The J pipes were left loose to allow for fit-up with the side pipes later.

Once this was done, I could re-intstall the footbox panel. Next came the headers, followed by the J pipes. These were fastened together with threaded rods I intalled on the headers. The J pipes were left loose to allow for fit-up with the side pipes later.

Prior to intalling the drive shaft, I noticed that the transmission housing was touching the 4″ round cross support beam. I decided to lift the transmission a bit, clean up some of the bottome of the transmission housing (if you call, I had cut this off earlier), and then added a shim under the transmission flex mount to create a gap between the housing and the chassis.

Prior to intalling the drive shaft, I noticed that the transmission housing was touching the 4″ round cross support beam. I decided to lift the transmission a bit, clean up some of the bottome of the transmission housing (if you call, I had cut this off earlier), and then added a shim under the transmission flex mount to create a gap between the housing and the chassis.

Next, I finished up the fuel line routing. I had left both the delivery and return lines long and without fittings so that I could cut them to length. Now that the engine was in I could finish this. I routed the lines as I wanted them, secured them in place and then cut them to length. I installed hose fittings, and then fastened them to the proper fuel ports on the EFI system .

I also cut the battery cable to length but will have to solder a new ring connector on the end and then fasten it to the starter solenoid.

I also cut the battery cable to length but will have to solder a new ring connector on the end and then fasten it to the starter solenoid.

The last step in this section was to install the drive shaft. This required getting the car to drive height, and then setting up the relative positions of the rear end and the transmission. I set the ride height at about 4 3/4″ in the front and 5″ in the rear. This will vary somewhat depending on the weight in the car, but it is good for now.

Using angle finders, I was able to determine the relative angles of the transmission to drive shaft and rear end to drive shaft. Ideally these are parallel to each other when in motion. Due to the fact the rear tends to “lift” a slight bit under load, the car is designed to set the rear end angle about 2 degress below the angle of the transmission. I was a bit low when first measured, so corrected this by lengthening the upper link arm. One problem we encountered was when we tried to slip the splined shaft into the transmission. It would just not slide on. We tried for some time, and finally called Tremec. We were told that there was an extra rubber stopper in the end of the shaft to stop any leakage during shipment. We were told to remove this, and then the shaft slid in easily.  The universal was then bolted to the rear end, and the drive train was complete.

More pictures can be seen in the Gallery.

More pictures can be seen in the Gallery.

To paraphrase a famous novel intro – it was the best of times, Phimosis

it was the worst of times, it was the best of times, and then some other stuff happened. Bottom line, the good news is the engine and transmission are in!

On Saturday, Feb. 18th, Pat, Julie Steve Reymann and I installed the engine and transmission. This was my first time dropping in an engine, so I had a bit of nerves as we began the day. Mostly the process was fairly smooth since we had plenty of hands to keep things under control. The engine bay is not huge and there is a support bar in the front that limits access, especially with a front sump oil pan. But, with the use of a leveler and taking lots of time, we were able to work the transmission down and through the tunnel and get the engine to drop into the motor mounts.

On Saturday, Feb. 18th, Pat, Julie Steve Reymann and I installed the engine and transmission. This was my first time dropping in an engine, so I had a bit of nerves as we began the day. Mostly the process was fairly smooth since we had plenty of hands to keep things under control. The engine bay is not huge and there is a support bar in the front that limits access, especially with a front sump oil pan. But, with the use of a leveler and taking lots of time, we were able to work the transmission down and through the tunnel and get the engine to drop into the motor mounts.

Once the engine was in, we needed to secure the transmission. There is an A-frame support bracket that mounts to the chassis beneath the transmission. After fitting it in and having to grind down a fat weld spot at one of the mounting points, we got this secured and then fastened the transmission in place. The last thing we needed to do for the day was tighten down the mounting bracket bolts. Nothing to it, right. Beer time getting close. Well, while tightening one of the bolts into the block, the bolt broke…..So, now we were faced with needing to get the bolt out. Patrick and I decided to call it a night and start the next day with trying to drill out the bolt and easy out the broken piece.

Once the engine was in, we needed to secure the transmission. There is an A-frame support bracket that mounts to the chassis beneath the transmission. After fitting it in and having to grind down a fat weld spot at one of the mounting points, we got this secured and then fastened the transmission in place. The last thing we needed to do for the day was tighten down the mounting bracket bolts. Nothing to it, right. Beer time getting close. Well, while tightening one of the bolts into the block, the bolt broke…..So, now we were faced with needing to get the bolt out. Patrick and I decided to call it a night and start the next day with trying to drill out the bolt and easy out the broken piece.

Again, easier said than done. We had to unbolt the transmission and raise the engine several inches to be able to get the motor mount removed and give us a bit of room to work. I later also removed the starter since that also freed up some space. The initial hole was drilled off center, so we were not able to use an easy out to remove the bolt. The easy out would just spin.  By this time it was late in the day, so we called it quits. Not sure what the next steps would be – I was really hoping I would not have to pull the engine and have it machined to get the bolt out.

The next day I talked with Steve again to give him an update. He thought we still had a chance to get it out, so with his help we spent a full day drilling, grinding, filing, swearing, picking and praying to see if we could enlarge the hole in the broken bolt and also get it centered enough to try an easy-out again or maybe to run a large drill through. If we could do that, maybe we could use a tap and clean out the remaining pieces.

That evening and the next morning I used a variety of Dremel bits and drill bits and continued to enlarge and center the hole. Using the sides of a small drill bit actually made the most progress. I was able to get a pretty good hole centered in the broken bolt by the time Steve got back that morning. After he took a look at it, he was pretty sure he could run a larger drill up through the hole, so he did that. That worked well, and Steve was then able to start a tap into the hole, and after slowly turning, cleaning and repeating the process for about an hour, we got the pieces out and were able to run a new bolt back up into the hole! We re-attached the mounting bracket, dropped the engine back down and re-fastened all the bolts. At last – after about 12 or more hours of extra effort – finished. Yahoo!

That evening and the next morning I used a variety of Dremel bits and drill bits and continued to enlarge and center the hole. Using the sides of a small drill bit actually made the most progress. I was able to get a pretty good hole centered in the broken bolt by the time Steve got back that morning. After he took a look at it, he was pretty sure he could run a larger drill up through the hole, so he did that. That worked well, and Steve was then able to start a tap into the hole, and after slowly turning, cleaning and repeating the process for about an hour, we got the pieces out and were able to run a new bolt back up into the hole! We re-attached the mounting bracket, dropped the engine back down and re-fastened all the bolts. At last – after about 12 or more hours of extra effort – finished. Yahoo!

Oh, the other stuff. I tried to fit up the driver side header to see how that fit and found out that the push out I had put into the driver side footbox near the gas pedal was too tall and the header would not fit. So, one more learning and a bit more rework. I will have to pull the panel out and re-build the push out so everything fits. More on that will come later. I always said I wanted to build this to learn more about cars, and you learn from mistakes. So, I am not being disappointed!!

More photos are in the Gallery.

1 comment